Co-Design and 3D Printing for Disabilities

2018

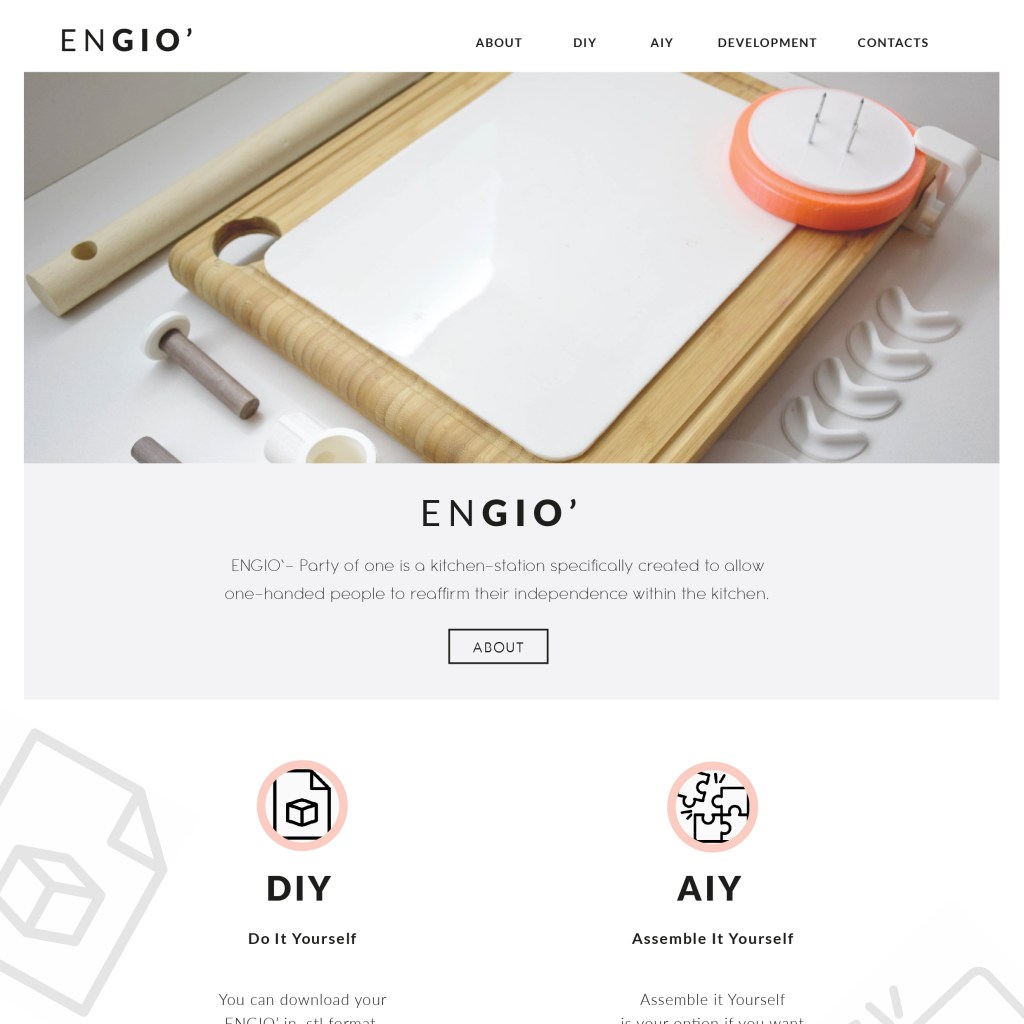

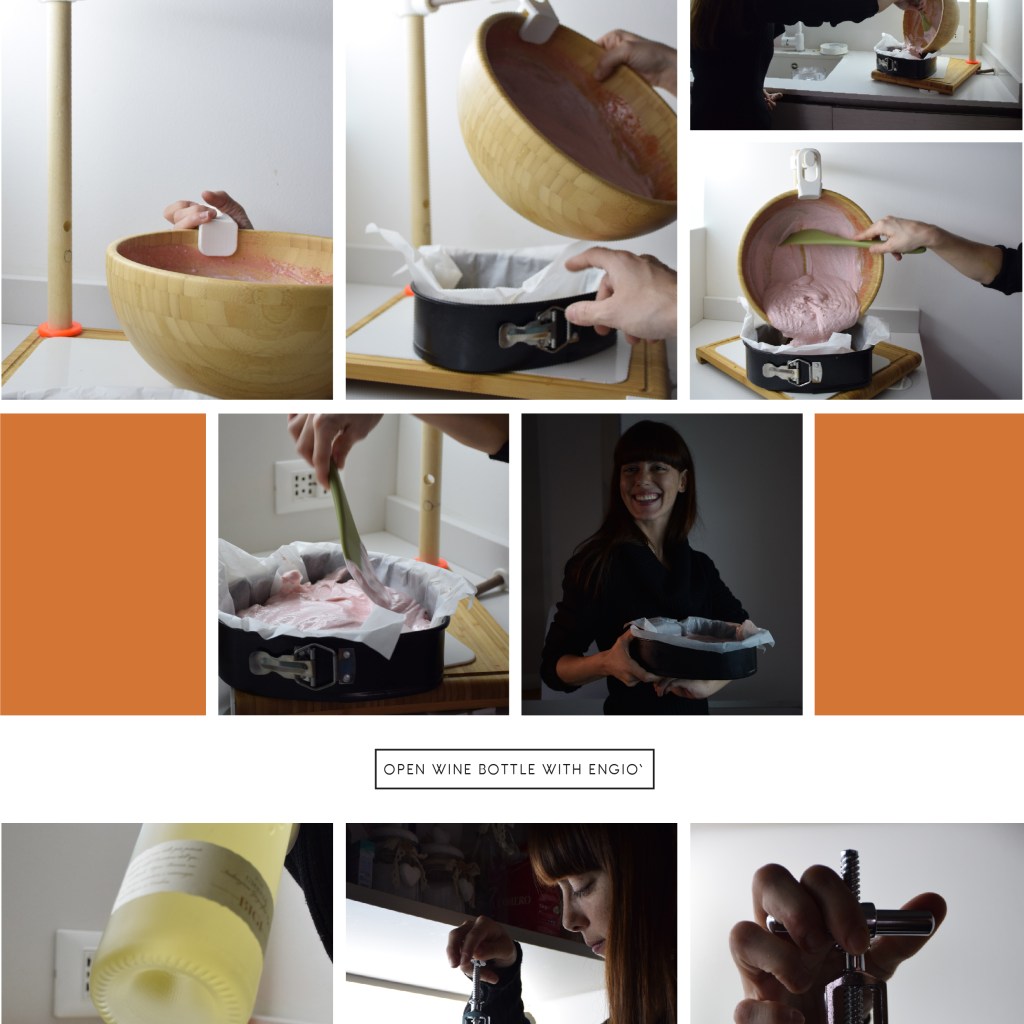

Engiò – Party of one is a co-designed and partially 3D Printed kitchen station specifically created to allow one-handed people to reaffirm their indipendence within the kitchen.

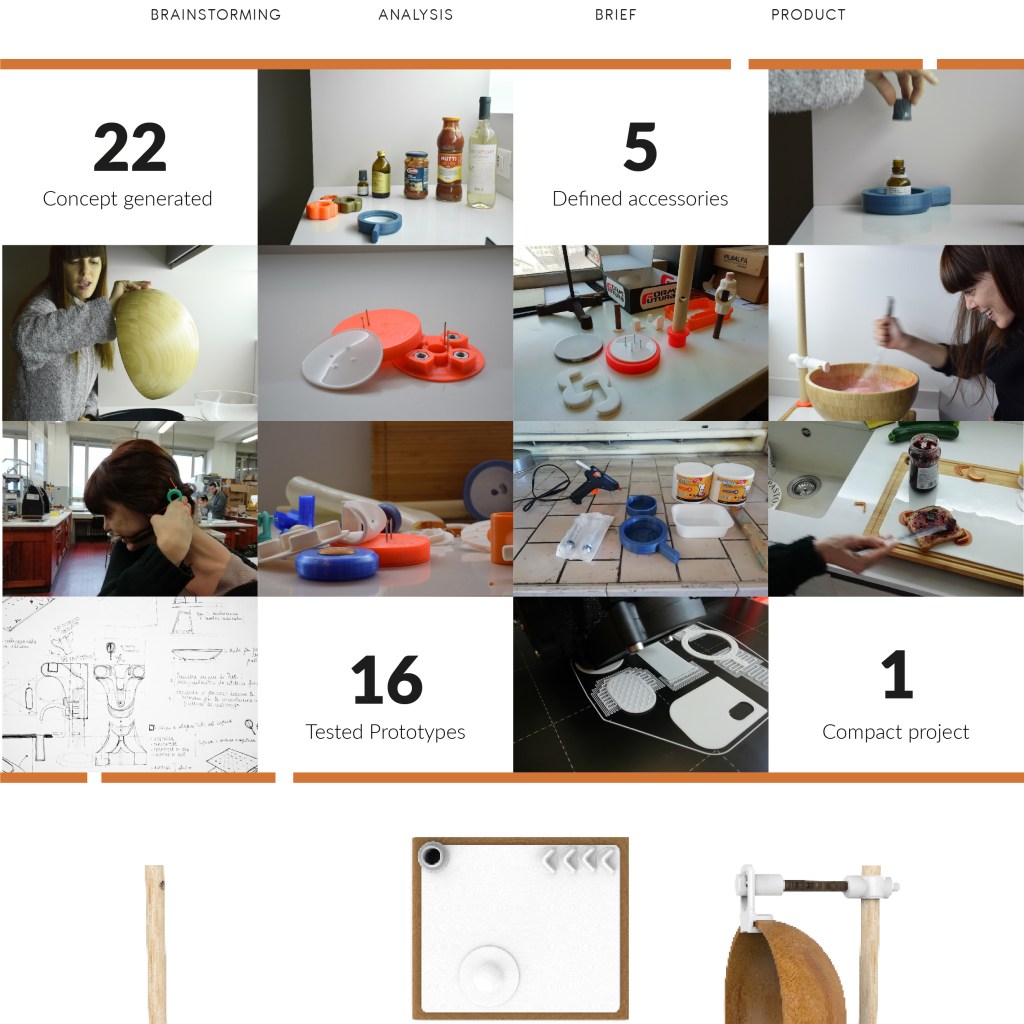

The project was born from a review of the design methodology tested in + Ability, an initiative promoted by + LAB, based on applicaed research about 3D printing and co-design in product development finalized in customi products that responds to the concrete needs of everyday life.

The thesis illustrates a research that aims to explore change in the delivery of health products / services, with particular attention towards low tech assistive technologies; exploring how the birth of new forms of collaboration and the diffusion of prototyping tools fast and affordable, they are promoting the development of projects that enhance the active participation of the user and his involvement in all stages of the design.

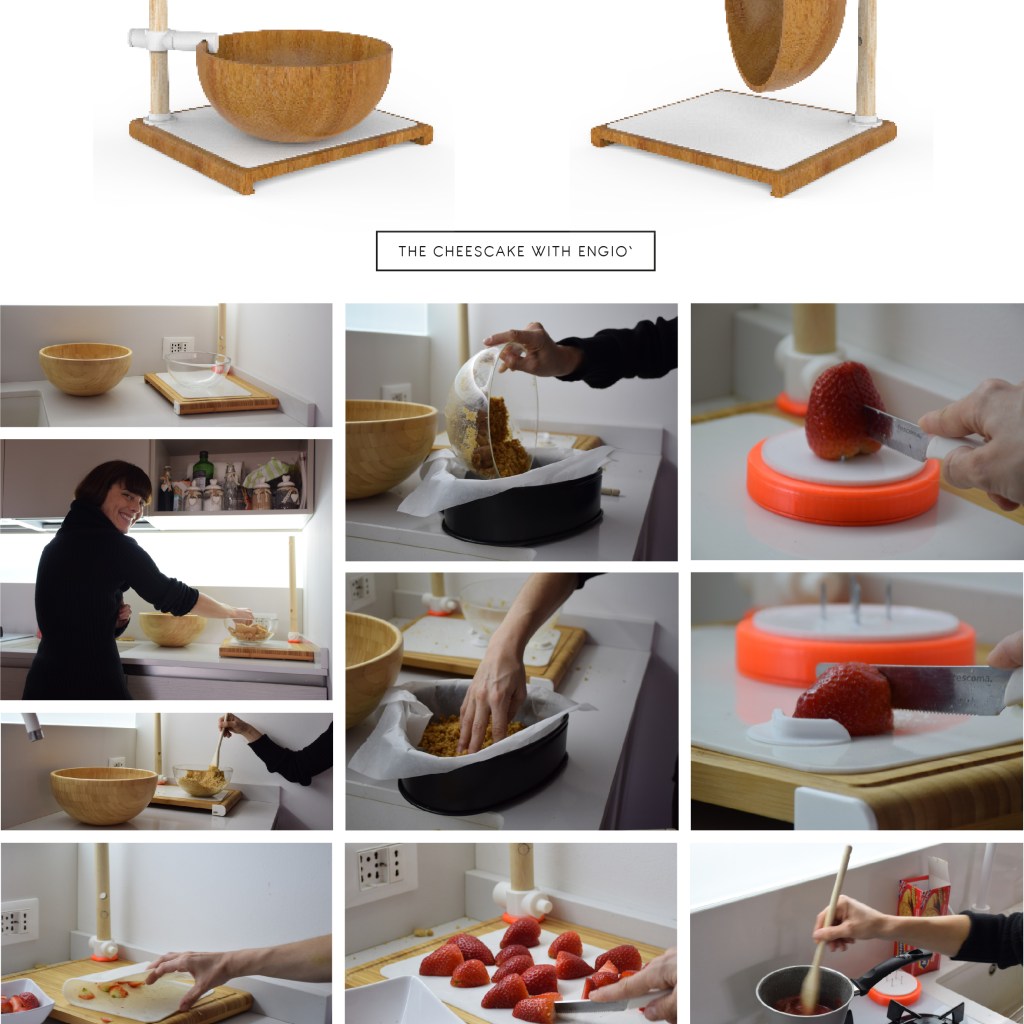

Further I present Giorgia, the user who took part in the project, and the methodology that was adopted to design the design path, from the survey on needs up to the development of the concept. Giorgia has a currently unknown disease that makes her hemidistonic, she can-t use full left side of body, arm and leg and she really likes to cook. The activities carried out are reported during the meetings and the outputs generated over time, documenting the evolution of the collaborative process, from the brainstorming phase to development and prototyping of the generated content.

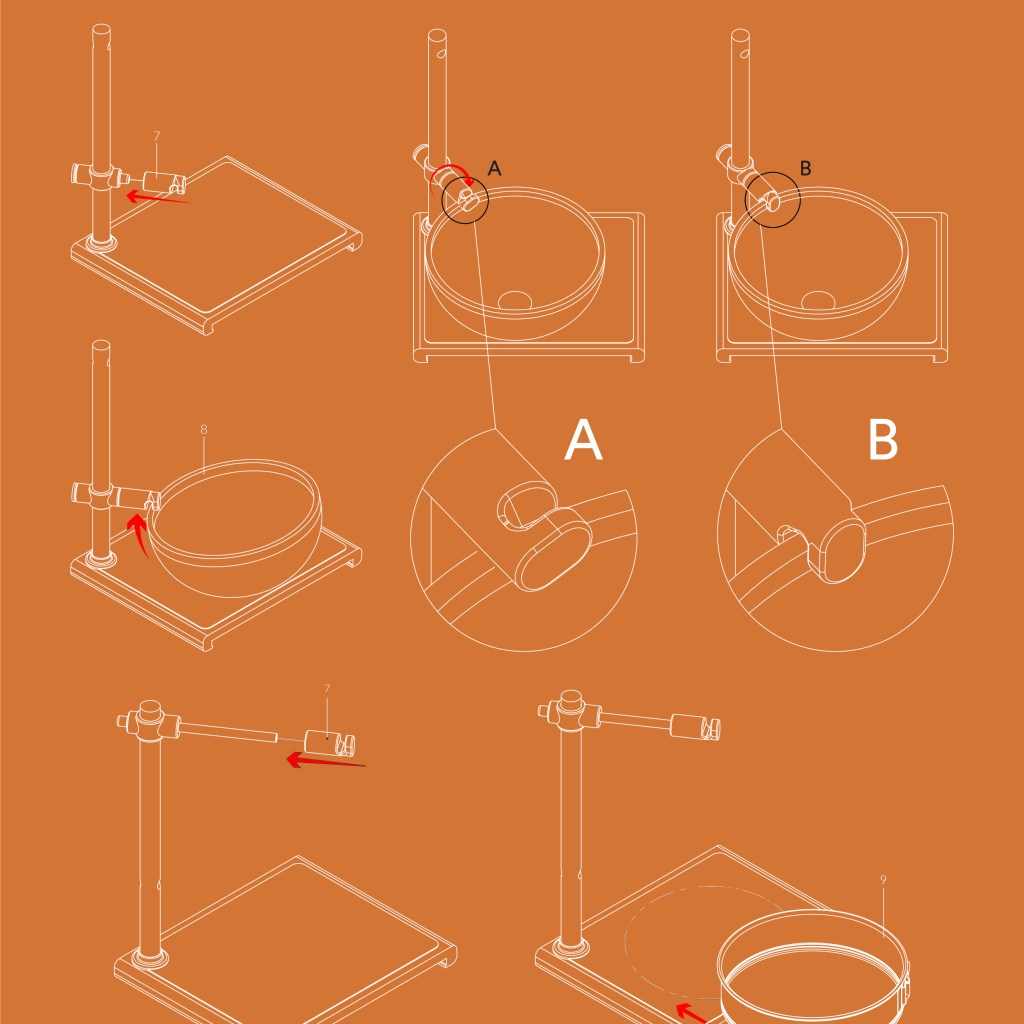

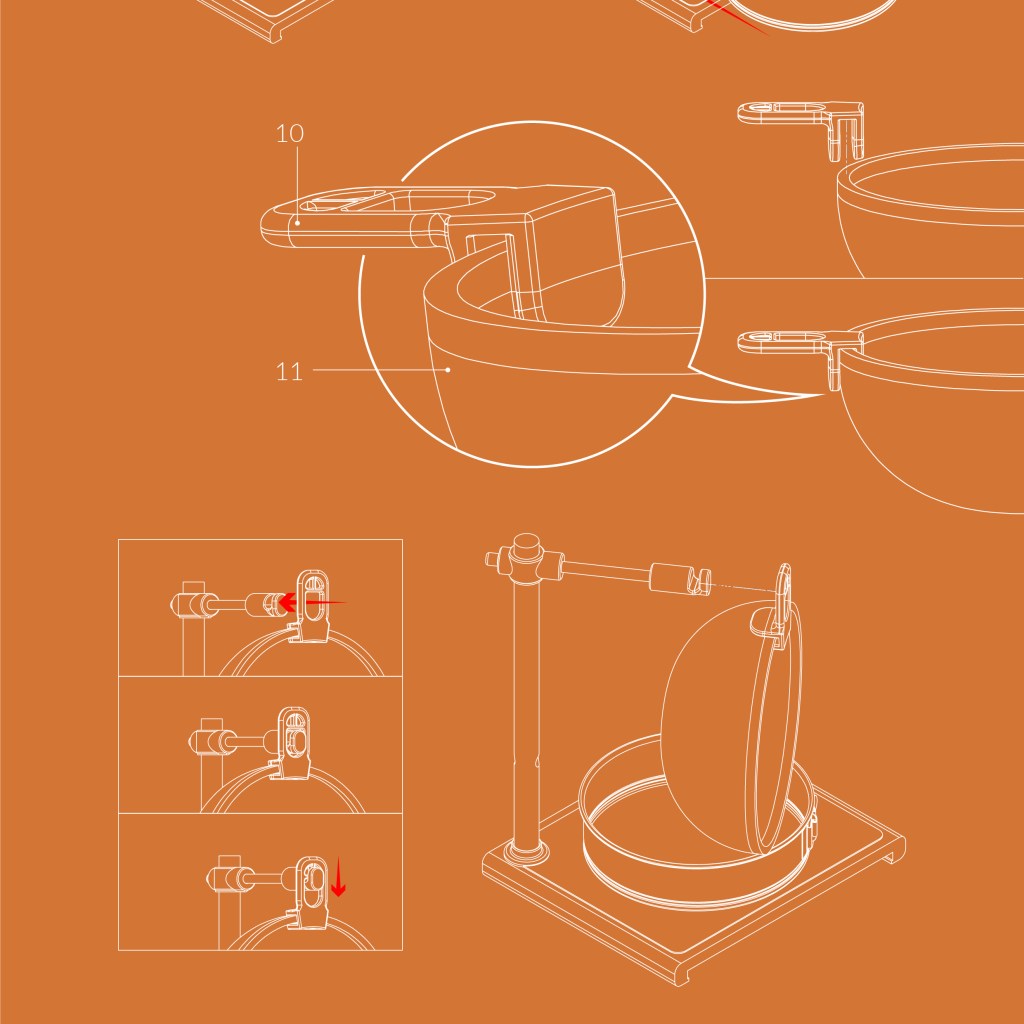

The design phase ended with the prototyping of a cutting board modular and configurable according to specific needs: to cut and peel fruit and vegetables, to spread creams on bread, to hold I stop a container to mix the dough and transfer it in a second container, to open cans and bottles in total autonomy. Peculiar aspects of the project are: the food compatibility of the materials used, the ease of assembly of the components and the study of elements able to perform multiple functions, in order to reduce the overall number of parts.

The project was engineered and optimized for the printing process 3D FDM and, to ensure structural solidity and an adequate lection of materials, several FEM analyzes were carried out, until obtaining the desired result. The conclusion of the thesis offers several food for thought regarding the possible dissemination, accessibility and replication of ENGIO ‘- Party of one, through different distribution channels.

After all, we manage to ENable GIOrgia!